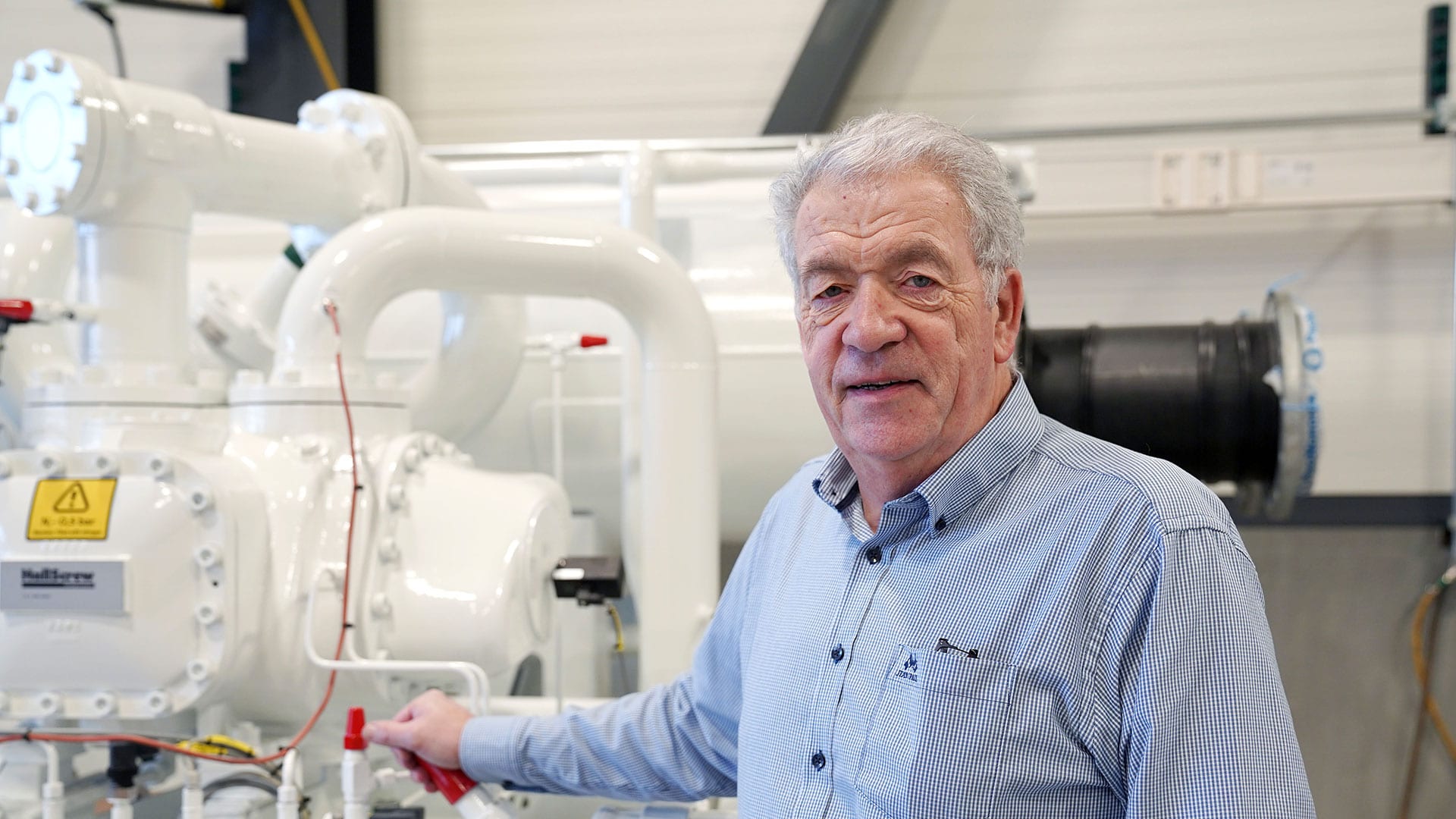

The arm of PTG currently based in Malmefjorden north of Molde has been refining its technology since the late 1970s for application to fish. Per Johansen, currently vice president sales at PTG Frionordica, was one of the three colleagues responsible.

Originally called Aquaterm and later FrioNordica, the company has built up comprehensive expertise with and experience of cooling and heating seawater over four decades.

PTG Frionordica is currently part of PTG, with parent company Perfect Temperature Group also owning PTG Kuldeteknisk, PTG Vest in Bergen, PTG Helgeland (previously Kjøleservice Helgeland) and PTG Multikulde in Bodø.

The arm of PTG currently based in Malmefjorden has been refining its technology since the late 1970s for application to fish. Per Johansen, currently vice president sales at PTG Frionordica, was one of the three colleagues responsible.

Smolt

It all began when Johansen worked with Stein Magne Årseth and Erik Holm at Bolsønes Verft in Molde, which had been making refrigerated seawater (RSW) system for fishing boats since 1965. The yard was a pioneer in applying new refrigeration technology to preserve the quality of herring and mackerel.

A new period began for the yard in 1979 when it won the job of manufacturing a heat pump for a smolt plant run by Sæter Fiskeoppdrett in Sunndalen. This was the first unit of its kind for smolt production.

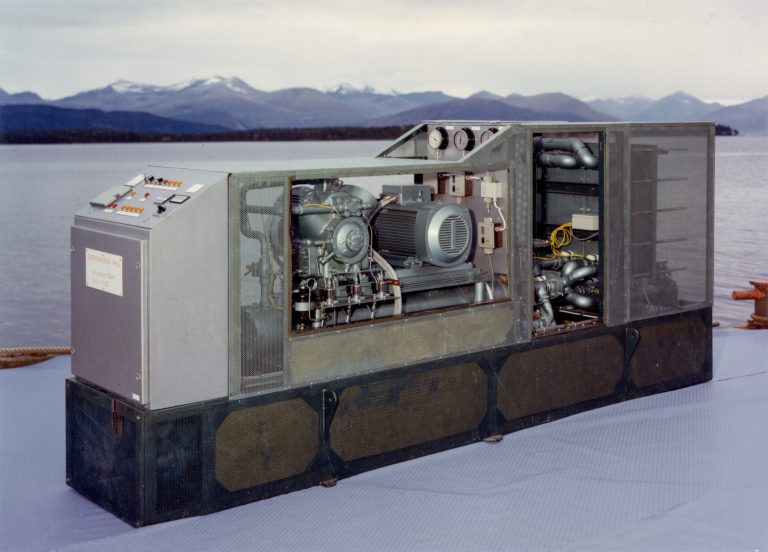

Bolsønes Verft, probably sometime in the 70’s.

Bolsønes Verft went into liquidation in 1983, and Johansen, Årseth and Holm established Aquaterm on the basis of the yard’s heat-pump activity. They built a new factory and office building on the site, and had up to 30 employees at peak.

A number of heat pumps and exchangers were built over time for smolt plants, and these became important products for Aquaterm. About 400 plants have been delivered so far, including a first delivery to Artec Aqua in 2003-04. This was installed at Bindalssmolt, part of the Sinkaberg-Hansen seafood company.

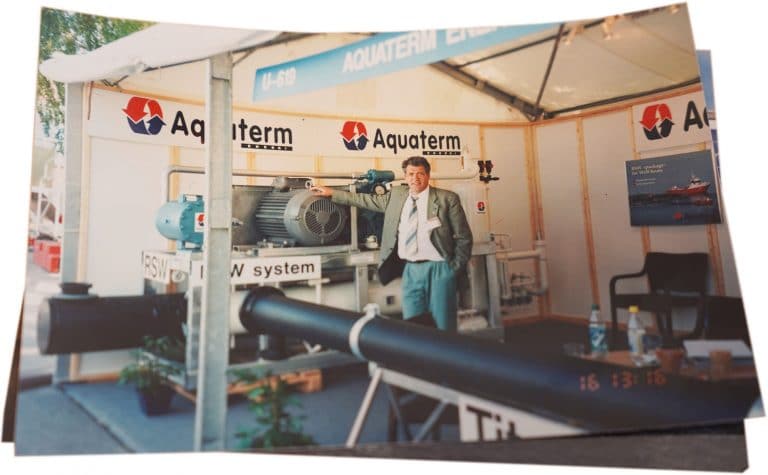

Bolsønes Verft went into liquidation in 1983, and Per Johansen, Stein Magne Årseth and Erik Holm established Aquaterm on the basis of the yard’s heat-pump activity. Here is a younger version of Per at an exhibition for Aquaterm.

Up and down

Although the aquaculture industry has been very important for companies along the Norwegian coast, it has had many upturns and downturns. These also affected Aquaterm.

The bankruptcy of the industry’s FOS sales organisation in 1991, combined with Norway’s bank crisis, many life difficult for the company. The dawning bank crisis had also contributed to the failure of Bolsønes Verft in the early 1980s.

Nevertheless, Aquaterm survived and eventually established a collaboration with Finsam in Grimstad. Per R Samuelsen at the latter had met Johansen when the pair were studying refrigeration technology at the Norwegian Institute of Technology (NTH) in Trondheim.

Finsam had been established as early as 1965, and was renowned in the fishing industry worldwide for its leadership with a number of ice machine types and ice storage systems. Its international business allowed Aquaterm to become involved in purposeful exports. PTG Frionordica still has a department in Grimstad and a subsidiary in Chile.

FrioNordica emerges

The first FrioNordica company was a joint venture between Aquaterm and Finsam Refrigeration, established as early as 2001 in Chile under the name Frionordica Refrigeración Limitada. It had offices in Puerto Montt and Concepcion to provide local service for products from the two companies.

Aquaterm and Finsam then established a joint sales company called FrioNordica in 2006, and merged two years later under this name.

FrioNordica has worked steadily to simplify, speed up and rationalise, giving priority always to developing its own products for salmon and fishing and for production in Norway. Key reasons for this have been short delivery times and control of quality.

All production was therefore concentrated in Molde during 2010, with manufacturing and the head office moving to new and modern premises in Malmefjorden the following year.

Manufacturing and the head office for PTG Frionordica moved from Molde to new and modern premises in Malmefjorden in 2011.

Qualified personnel

Molde has been known over more than 70 years for its large and highly qualified involvement in developing and building cranes. The offshore industry flourished from the late 1990s to 2014, making it difficult for FrioNordica to compete over qualified personnel in Molde. The supply of industrial sites was also limited there.

So Johansen turned his attention to the neighbouring local authority of Fræna (now Hustadvika) and Malmefjorden. This is one of the biggest farming communities between Stavanger and Trondheim, and also hosts a number of industry and export companies such as Tine, Moxy Trucks and Hustadmarmor.

Given this work culture and industrial background, it was easier to recruit able workers who suited FrioNordica there. More people, including residents of Molde, have now grasped the development opportunities offered by the seafood sector and PTG in Malmefjorden.

Heat pump system made at Bolsønes Verft in the period between 1980–84.

Big leap

“Progress has been huge,” reflects Johansen. “Before I retire, we’ll have delivered heat pumps to our first fish farm. That’s a big milestone for me, while this project gives PTG a unique opportunity to test its products in full scale.

“We’re now building the energy system of tomorrow for land-based aquaculture here in Malmefjorden. These are large heat pumps by Norwegian standards. We’ve made a big leap from the first heat pumps with an output of 60–70 kW which I helped to build more than 40 years ago to the Salmon Evolution units of 5 000–6 000 kW.”

RELATED NEWS